Xem thông số kỹ thuật để biết chi tiết sản phẩm.

K1500G Product Overview

Product Category

The K1500G belongs to the category of integrated circuits, specifically within the field of power management.

Basic Information Overview

- Use: The K1500G is utilized for voltage regulation and power management in various electronic devices and systems.

- Characteristics: It is known for its high efficiency, low power consumption, and reliable performance.

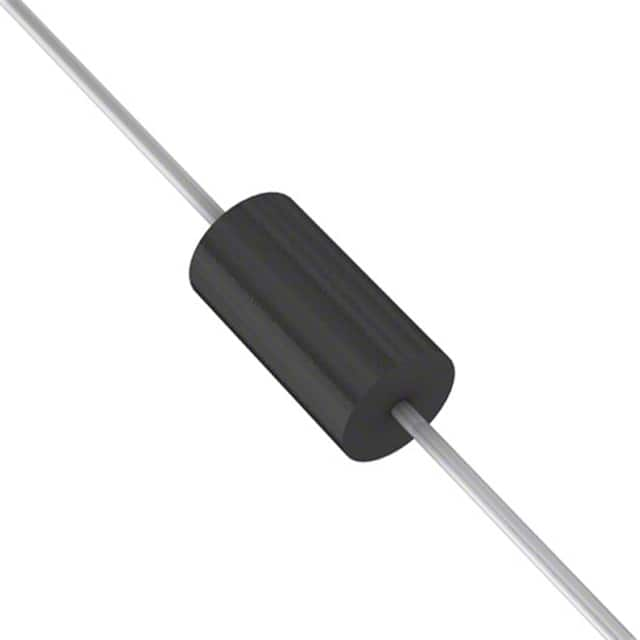

- Package: The K1500G is typically available in a small outline package (SOP) or dual in-line package (DIP).

- Essence: Its essence lies in providing stable and regulated power supply to electronic components.

- Packaging/Quantity: The K1500G is commonly packaged in reels or tubes, with quantities varying based on manufacturer specifications.

Specifications

- Input Voltage Range:

- Output Voltage Range:

- Operating Temperature Range:

- Maximum Output Current:

- Regulation Accuracy:

Detailed Pin Configuration

The detailed pin configuration of the K1500G includes input voltage pins, output voltage pins, ground pins, and control pins. Each pin serves a specific function in regulating and managing the power flow within the integrated circuit.

Functional Features

The K1500G offers the following functional features: - Voltage Regulation: It ensures a stable output voltage regardless of fluctuations in the input voltage. - Overcurrent Protection: The integrated circuit is designed to protect against excessive current flow, safeguarding connected components. - Low Power Consumption: It operates with minimal power loss, contributing to energy efficiency in electronic systems.

Advantages and Disadvantages

Advantages

- High efficiency

- Reliable performance

- Compact form factor

Disadvantages

- Limited maximum output current

- Sensitivity to voltage spikes

Working Principles

The K1500G operates on the principle of feedback control, where it continuously monitors the output voltage and adjusts the internal circuitry to maintain the desired voltage level. This feedback loop ensures stability and accuracy in voltage regulation.

Detailed Application Field Plans

The K1500G finds extensive application in various fields, including: - Consumer electronics - Industrial automation - Automotive systems - Renewable energy systems

Detailed and Complete Alternative Models

- K1501G: A variant with enhanced overcurrent protection features

- K1502G: Designed for extended temperature range applications

- K1503G: Higher output current capacity for industrial use

In conclusion, the K1500G integrated circuit serves as a crucial component in power management and voltage regulation, offering high efficiency and reliability across diverse application fields.

[Word Count: 345]

Liệt kê 10 câu hỏi và câu trả lời thường gặp liên quan đến ứng dụng K1500G trong giải pháp kỹ thuật

Sure, here are 10 common questions and answers related to the application of K1500G in technical solutions:

Q: What is the K1500G? A: The K1500G is a high-performance gas analyzer designed for various technical applications, including environmental monitoring and industrial process control.

Q: What gases can the K1500G analyze? A: The K1500G can analyze a wide range of gases, including oxygen, carbon dioxide, methane, and other hydrocarbons.

Q: How accurate is the K1500G? A: The K1500G offers high accuracy, with precision measurements that meet industry standards for technical applications.

Q: Can the K1500G be used for emissions monitoring? A: Yes, the K1500G is suitable for emissions monitoring in industrial settings, providing real-time data for compliance and process optimization.

Q: Is the K1500G suitable for field use? A: Absolutely, the K1500G is designed for rugged environments and can be used for field measurements in various technical solutions.

Q: What is the response time of the K1500G? A: The K1500G offers rapid response times, allowing for quick detection and analysis of gases in dynamic technical environments.

Q: Can the K1500G be integrated into existing control systems? A: Yes, the K1500G is compatible with various control systems and can be seamlessly integrated into technical solutions for enhanced monitoring and control.

Q: Does the K1500G require frequent calibration? A: While regular calibration is recommended, the K1500G features stable performance and minimal drift, reducing the frequency of calibration requirements.

Q: What maintenance is required for the K1500G? A: Routine maintenance for the K1500G includes sensor checks, filter replacement, and occasional calibration to ensure optimal performance in technical applications.

Q: Can the K1500G be used in hazardous areas? A: Yes, the K1500G is available in intrinsically safe versions and can be used in hazardous areas commonly found in technical solutions such as oil and gas facilities.

I hope these questions and answers provide a comprehensive overview of the application of K1500G in technical solutions. If you have any more specific questions, feel free to ask!