Xem thông số kỹ thuật để biết chi tiết sản phẩm.

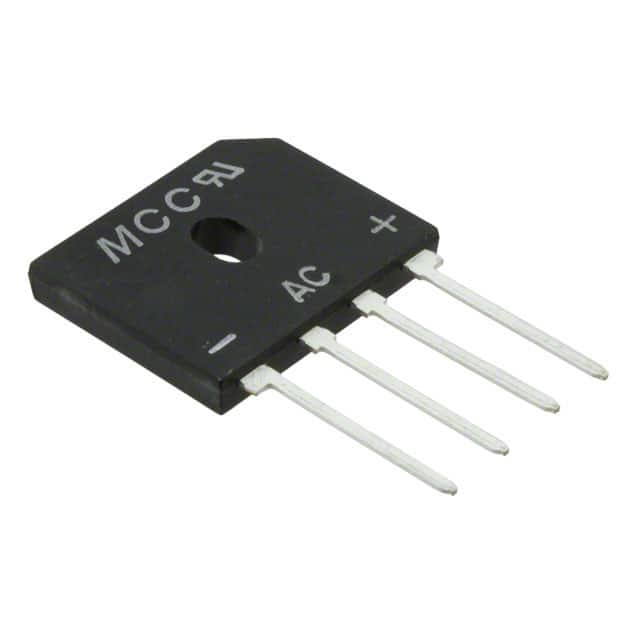

GBU4G-BP

Product Overview

Category: Rectifier Bridge

Use: Converts alternating current (AC) to direct current (DC)

Characteristics: High efficiency, low forward voltage drop, compact design

Package: Through-hole or surface mount

Essence: Essential component for power supply and motor drive applications

Packaging/Quantity: Typically packaged in reels or tubes, quantity varies by manufacturer

Specifications

- Maximum Average Forward Current: 4A

- Peak Repetitive Reverse Voltage: 400V

- Maximum DC Blocking Voltage: 400V

- Operating Temperature Range: -55°C to +150°C

- Mounting Type: Through Hole or Surface Mount

- Package / Case: GBU

Detailed Pin Configuration

The GBU4G-BP rectifier bridge typically consists of four pins arranged in a square configuration. The pinout is as follows: 1. Pin 1: AC Input + 2. Pin 2: AC Input - 3. Pin 3: DC Output + 4. Pin 4: DC Output -

Functional Features

- Efficiently converts AC to DC

- Low forward voltage drop minimizes power loss

- Compact design saves space on circuit boards

- Reliable performance in various operating conditions

Advantages and Disadvantages

Advantages: - High efficiency - Low forward voltage drop - Compact design

Disadvantages: - May require heat sinking in high-power applications - Limited maximum average forward current

Working Principles

The GBU4G-BP rectifier bridge operates by utilizing diodes to conduct current in only one direction, allowing it to convert the alternating current from the input into a direct current output.

Detailed Application Field Plans

The GBU4G-BP is commonly used in the following applications: - Power supplies - Motor drives - Welding equipment - Battery chargers - Industrial automation

Detailed and Complete Alternative Models

- GBU6G-BP: Higher maximum average forward current

- GBU8G-BP: Higher peak repetitive reverse voltage

- GBU10G-BP: Higher maximum DC blocking voltage

In conclusion, the GBU4G-BP rectifier bridge is a crucial component in various electronic applications, offering high efficiency and reliable performance. Its compact design and low forward voltage drop make it an ideal choice for power supply and motor drive circuits.

[Word Count: 313]

Liệt kê 10 câu hỏi và câu trả lời thường gặp liên quan đến ứng dụng GBU4G-BP trong giải pháp kỹ thuật

Sure, here are 10 common questions and answers related to the application of GBU4G-BP in technical solutions:

What is GBU4G-BP?

- GBU4G-BP is a bridge rectifier module designed for use in high-reliability applications such as power supplies and industrial controls.

What is the maximum voltage rating of GBU4G-BP?

- The maximum voltage rating of GBU4G-BP is typically 400 volts.

What is the maximum current rating of GBU4G-BP?

- The maximum current rating of GBU4G-BP is typically 4 amperes.

What are the typical applications of GBU4G-BP?

- GBU4G-BP is commonly used in AC to DC conversion circuits, motor drives, and general purpose rectification.

What is the operating temperature range of GBU4G-BP?

- The operating temperature range of GBU4G-BP is typically -55°C to 150°C.

Does GBU4G-BP require a heat sink for operation?

- Depending on the application and power dissipation, GBU4G-BP may require a heat sink for optimal performance.

Is GBU4G-BP RoHS compliant?

- Yes, GBU4G-BP is RoHS compliant, making it suitable for use in environmentally sensitive applications.

Can GBU4G-BP be used in three-phase rectification circuits?

- Yes, GBU4G-BP can be used in three-phase rectification circuits by connecting multiple modules in the appropriate configuration.

What are the packaging options available for GBU4G-BP?

- GBU4G-BP is available in industry-standard packages such as D2PAK, D3PAK, and TO-220.

Are there any recommended layout considerations for using GBU4G-BP in PCB designs?

- It is recommended to minimize trace lengths and provide adequate thermal relief for the mounting pads to ensure proper performance of GBU4G-BP in PCB designs.